Heat Treatment Processes for Duplex Stainless Steel Weldments

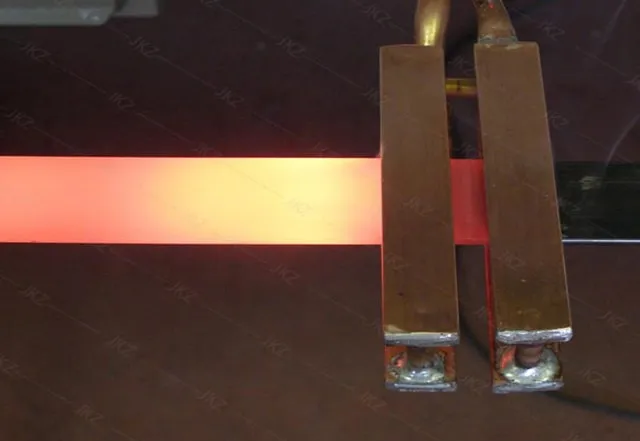

Duplex stainless steels (DSS) are truly remarkable materials, prized for their exceptional combination of high strength and excellent corrosion resistance. This unique balance stems from their biphasic microstructure, comprising roughly equal proportions of ferrite (α) …