Steel is a versatile and widely used material in various industries, ranging from construction to manufacturing. When subjected to high temperatures, steel undergoes a fascinating transformation, displaying a range of vibrant colors.

These heat colors not only add aesthetic appeal but also provide valuable information about the steel’s temperature and potential applications. In this article, we will explore the different heat colors for steel and their significance.

Understanding Heat Coloring

When steel is heated, it goes through a process called oxidation, where the surface reacts with oxygen in the air. This reaction forms a layer of oxide on the steel’s surface, which gives rise to the characteristic heat colors. The colors observed depend on the temperature reached during the heating process.

You may be familiar with the term “red-hot” when referring to steel, but in reality, steel undergoes a transformation of colors and shades as it heats up, starting from a dull red and progressing towards a white-hot state.

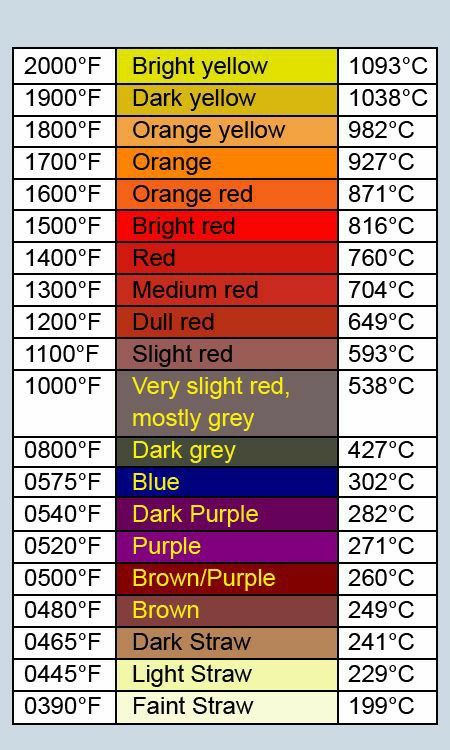

Heat Colors and Their Temperatures:

- Straw Yellow (around 430°C / 806°F): At this temperature, steel starts to exhibit a faint yellow color. This heat color indicates that the steel is approaching its critical temperature, which is the point at which it undergoes significant changes in its microstructure.

- Brown (around 480°C / 896°F): As the temperature increases, the steel transitions from straw yellow to a light brown color. This heat color signifies that the steel is nearing the critical temperature and is close to becoming non-magnetic.

- Purple (around 540°C / 1004°F): As the steel continues to heat, it turns into a purple hue. This heat color indicates that the steel is approaching the critical temperature and is about to undergo a phase transformation.

- Blue (around 600°C / 1112°F): At this temperature, the steel takes on a blue color. This heat color suggests that the steel has surpassed its critical temperature and is now in the austenitic phase, which is characterized by increased ductility.

- Dark Blue (around 650°C / 1202°F): As the temperature rises further, the blue color deepens into a dark blue shade. This heat color indicates that the steel is approaching its maximum recommended temperature for heat treatment processes.

- Grey (around 700°C / 1292°F): At this temperature, the steel starts to lose its color and appears grey. This heat color signifies that the steel is nearing its melting point and should be handled with caution.

- White (above 900°C / 1652°F): When steel reaches extremely high temperatures, it turns white. This heat color indicates that the steel is in a molten state and has surpassed its melting point.

What is the importance of Heat Coloring Chart?

Observing color changes in steel during heat treatment is indeed a common method to estimate its temperature. The colors that appear during heating can provide a rough indication of the steel’s temperature. However, it is important to note that this method is subjective and can vary depending on lighting conditions, personal perception, and the specific composition of the steel being treated.

To accurately determine the temperature of the steel based on color changes, a chart or table showing the actual colors of steel at various temperatures is highly recommended. Such a chart provides a reference point for identifying the colors and their corresponding temperatures more precisely. It helps ensure consistency and accuracy in the heat-treating process.

If you are planning to perform an actual heat-treating operation, obtaining a chart or table specific to the type of steel you are working with would be beneficial. This will help you make more informed judgments and improve the success of the heat-treating process.

Utilizing Heat Colors for Steel

Heat colors for steel have practical applications in various industries. Here are a few examples:

- Heat Treatment: Heat treating steel involves subjecting it to specific temperatures to alter its mechanical properties. By monitoring the heat colors, professionals can determine when the steel has reached the desired temperature for quenching or tempering processes.

- Welding: During welding, heat colors can indicate the temperature distribution in the welded joint. This information helps welders ensure proper heat input and avoid overheating or underheating the steel.

- Forging: Blacksmiths and metalworkers use heat colors to gauge the temperature of the steel during the forging process. This allows them to achieve the desired malleability and shape the steel accordingly.

- Metal Identification: Heat colors can also aid in identifying different types of steel. Each steel alloy exhibits unique heat colors, allowing experts to differentiate between various grades of steel.

Conclusion:

Heat colors for steel provide valuable insights into the material’s temperature and properties. By understanding the significance of these colors, professionals in industries such as heat treatment, welding, and forging can make informed decisions and achieve desired outcomes. Whether it’s for aesthetic purposes or practical applications, heat colors add an element of fascination and utility to the world of steel.