SAE 5160, also known as JIS G4801, is a highly sought-after chromium spring steel with a medium to high carbon content (0.60%). This steel has gained immense popularity, primarily due to its affordability, exceptional toughness, and resilience, making it a preferred choice for truck leaf springs.

Its remarkable toughness has also made it a favored material for crafting swords, with a hardness typically ranging in the low 50s Rc. Moreover, 5160 is extensively employed in the production of large knives, including versatile bowies and heavy-duty choppers.

However, in recent times, there has been a growing trend among knifemakers to opt for 80CRV2 steel instead. This alternative is often regarded as “5160 on steroids” for knife blades, as it offers enhanced performance characteristics over 5160.

5160 Spring steel Chemical Composition

Understanding the chemical composition of 5160 spring steel is crucial for comprehending its mechanical properties and suitability for various applications. This medium to high carbon (0.60%) chromium steel exhibits exceptional toughness and resilience, making it a popular choice for springs, knives, and other demanding applications.

In the following table, we present the detailed chemical composition of 5160 spring steel, highlighting the elements that contribute to its unique characteristics.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.56-0.64 |

| Manganese (Mn) | 0.75-1.00 |

| Silicon (Si) | 0.15-0.35 |

| Chromium (Cr) | 0.70-0.90 |

| Phosphorus (P) | 0.035 (max) |

| Sulfur (S) | 0.040 (max) |

Table: Chemical Composition of 5160 Spring Steel

5160 Spring steel Mechanical & Physical Properties

| Property | Value |

|---|---|

| Tensile Strength | 1900 to 2100 MPa |

| Yield Strength | 1600 to 1800 MPa |

| Elongation | 10% to 15% |

| Modulus of Elasticity | 210 GPa |

| Hardness (HRC) | 57 to 63 |

| Density | 7.85 g/cm³ |

| Melting Point | 1420°C (2588°F) |

| Thermal Conductivity | 46.6 W/m·K |

| Coefficient of Thermal Expansion | 11.5 × 10^-6/°C |

SAE 5160 Spring steel Heat Treatment

AISI 5160H, known for its exceptional flexibility, offers the advantage of being heat treatable to achieve different hardness levels suited for various operating environments. While this steel contains chromium, it is important to note that the chromium content is not sufficiently high (<13%) to significantly reduce its susceptibility to corrosion.

Consequently, it becomes crucial to protect the knife blade made from AISI 5160H by applying a rust-preventative coating such as Fluid Film or any other protective coating. This protective measure ensures that the material is shielded from direct exposure to the elements, thereby preserving its performance and longevity.

5160 spring steel exhibits remarkable hardness, with a hardening capability ranging from 57 to 63 HRC (840 HV). This high hardness level makes 5160 an ideal choice for applications requiring excellent wear resistance and durability.

During the hardening process, it is crucial to protect the steel from oxidation and decarburization, as these can negatively impact the desired properties of the material. To prevent these issues, the use of anti-scale compounds such as Cordusal, Turco, and ATP-641 is highly recommended. These compounds form a protective barrier that helps prevent the formation of scale and oxidation on the surface of the steel.

Normalizing: Achieving the Ideal Microstructure

Normalizing is a crucial step in the heat treatment of 5160 spring steel. To achieve the desired microstructure of pearlite, the blade needs to be heated in a furnace to around 870°C (1600°F) and held at that temperature for 20 minutes. Afterward, the blade should be allowed to air cool to room temperature. This normalizing process helps refine the steel’s microstructure, enhancing its mechanical properties.

Annealing: Enhancing Ductility

Annealing is another important heat treatment step for 5160 spring steel. To improve ductility, the blade should be heated to 677°C (1250°F) and held at that temperature for 2 hours. This annealing process helps relieve internal stresses and promotes the transformation of retained austenite to bainite, which increases the steel’s ductility.

DET (Divorced Eutectoid Transformation): Seeking Ferrite and Carbide Structures

In contrast to normalizing and annealing, the DET process aims to achieve specific ferrite and carbide structures in the steel. For this step, the blade should be heated to 750°C (1380°F) for 10 minutes and then allowed to cool in air. DET provides a different microstructure compared to normalizing and annealing, offering unique properties for specific applications.

Effect of Different Austenitizing Temperatures on Grain Size

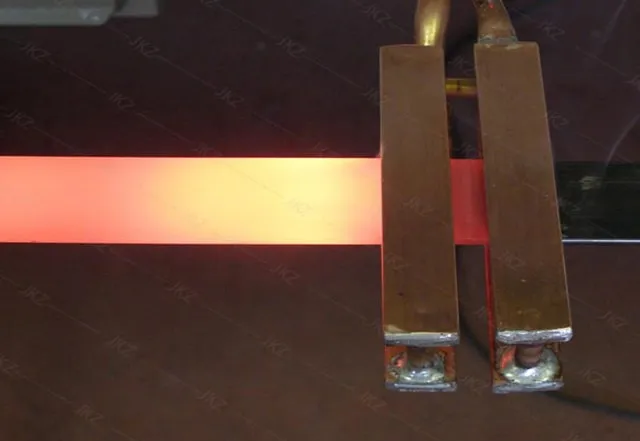

The austenitizing temperature plays a significant role in determining the grain size of 5160 spring steel. The photo provided by jorge iruzubieta showcases the effect of various austenitizing temperatures ranging from 830°C to 870°C.

Understanding the relationship between austenitizing temperature and grain size is essential for tailoring the steel’s properties to meet specific requirements.

Austenitizing and Quenching: Achieving Desired Hardness

To achieve the desired hardness in 5160 spring steel, the austenitizing temperature is crucial. The recommended range for furnace hardening is 829°C to 850°C (1525°F to 1562°F), with the sweet spot being around 840°C (1544°F).

The soak time in the furnace varies depending on the thickness of the blade, ranging from 5 minutes for thinner sections to 30 minutes for thicker sections.

Choosing the right quenching media is critical to obtain full martensite conversion and suppress the bainite phase. Fast oils are generally recommended due to their ability to provide acceptable results with reduced chances of blade failure compared to brine/water quenching. Interrupted water quenching in heated brine or water-soap solutions can also be suitable for certain applications.

Cryogenic Processing: Limited Benefits for Knife Blades

Cryogenic treatments, despite the potential benefits they offer for spring steel, may not yield significant positive effects for knife blades made from 5160 steel.

The results from studies on cryogenic cycles indicate that they may not enhance fatigue and impact resistance for knife blades. Thus, if ultimate toughness is the primary goal, cryogenic treatments can be skipped.

Tempering: Reducing Hardness and Increasing Ductility

Tempering is a critical step to reduce hardness, increase ductility, and relieve internal stresses in 5160 spring steel. During tempering, the transformation of retained austenite to bainite usually occurs.

It is important to note that retained austenite cannot be completely avoided when quenching at room temperature.

The recommended tempering temperature ranges from 150°C (300°F) to 180°C (350°F), depending on the desired hardness. The blade should be tempered twice for one hour each time.

The recommended hardness after tempering ranges from 58 to 60 HRC, with lower hardness suitable for tough applications and higher hardness for sharp slicers with minimal chopping requirements.