Surface hardening processes have emerged as effective techniques to enhance the surface properties of materials, making them more resistant to wear, corrosion, and fatigue. This article explores the different surface hardening processes, their applications, and the benefits they offer.

What is Surface Hardening?

Surface hardening refers to a group of heat treatment processes that modify the surface layer of a material while maintaining the core properties. Unlike traditional heat treatment methods that alter the entire material’s properties, surface hardening selectively strengthens the outer layer, resulting in improved wear resistance, hardness, and toughness.

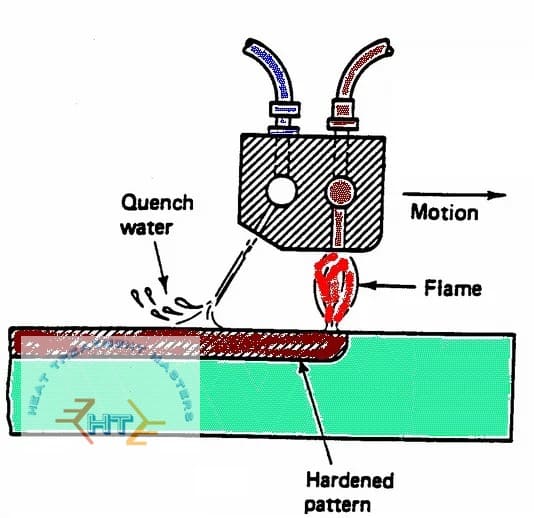

1. Flame Hardening

Flame hardening is a technique used to increase the hardness of metal surfaces. It involves directing a flame towards the metal, heating it to the desired temperature. The heated metal is then rapidly cooled by quenching it in water or oil, resulting in a hardened surface layer. This method is commonly employed for low to medium-carbon steel and cast iron.

One advantage of flame hardening is its speed. It can quickly achieve a high level of hardness on metal surfaces. Moreover, it allows for selective hardening of specific areas on a metal workpiece. However, uneven heating and cooling can lead to distortion or warping. Additionally, a brittle surface layer may form, making the workpiece prone to cracking under high stress.

2. Through Hardening Process

Through hardening, also known as quenching and tempering, involves heating a workpiece to a high temperature and then rapidly cooling it using a quenching medium. The workpiece is subsequently tempered at a lower temperature to reduce brittleness and enhance toughness. This method is suitable for medium to high-carbon steels.

Similar to flame hardening, through hardening can produce materials with high hardness, strength, durability, and toughness. However, distortion may still occur during the process. If not tempered correctly, workpieces can lose their ductility and toughness.

3. Case Hardening

Case hardening is performed by heating metal in an environment rich in carbon to allow carbon absorption into the surface layer. The metal is then quenched to rapidly cool it down, resulting in a hardened surface layer with a softer, more ductile core. This method is applicable to low-carbon steels and alloy steels.

This process involves introducing carbon or nitrogen into the surface layer of a low-carbon steel component. Case hardening methods include

- Carburizing,

- Nitriding, and

- Carbonitriding.

These techniques create a hardened outer layer while retaining a tough and ductile core.

Compared to flame hardening, case hardening can create a harder surface layer on workpieces. It also enables selective hardening without affecting the rest of the workpiece. However, this process can be slower and more expensive than other hardening methods. The surfaces may also be susceptible to chipping or cracking under high stress.

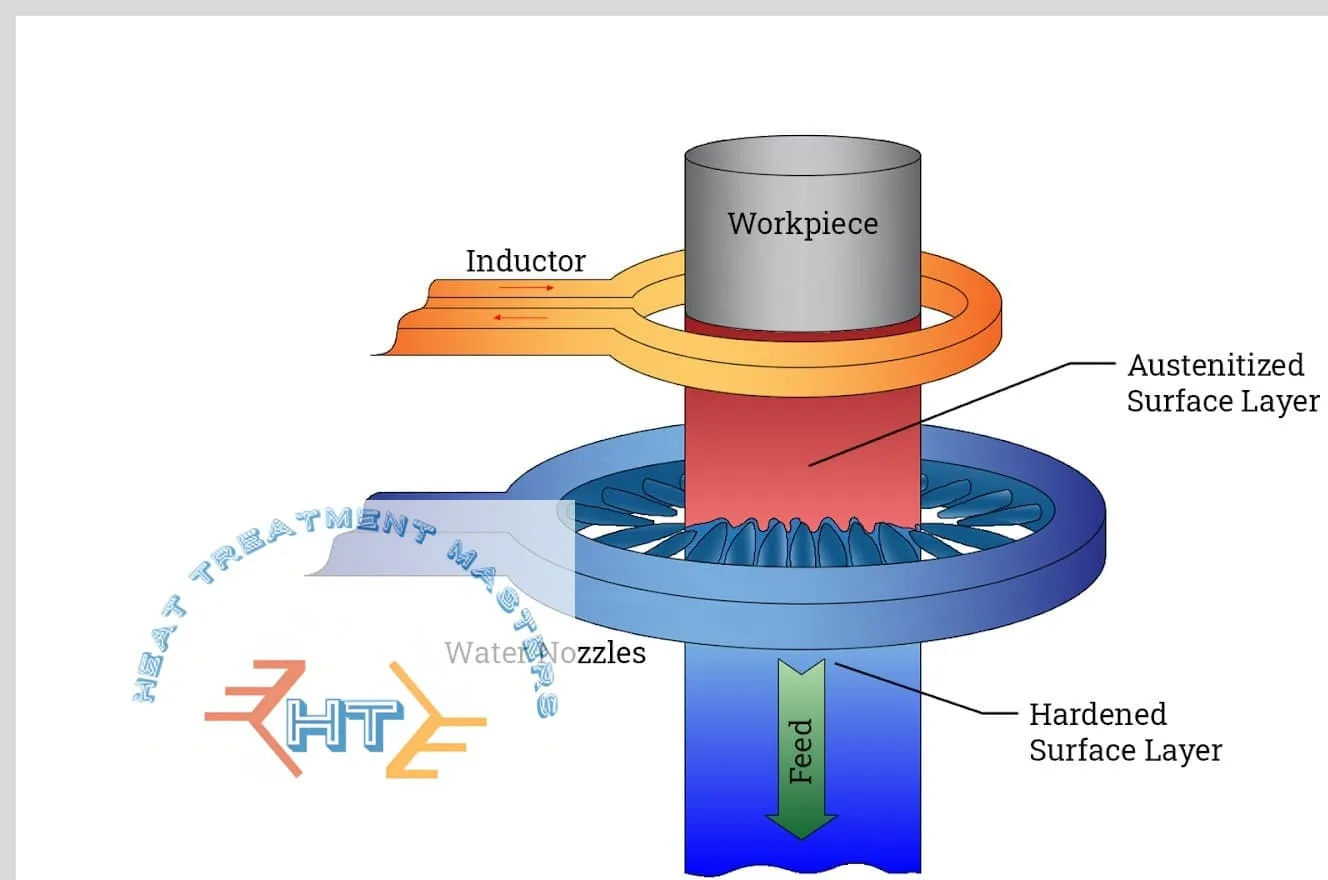

4. Induction Hardening

Induction hardening utilizes high-frequency electromagnetic fields to heat the surface of a component rapidly. The heated area is then quenched, resulting in a hardened surface layer. This technique is commonly used for gears, shafts, and other components subjected to high wear.

Induction hardening is used for rapidly and uniformly hardening the surface layer of metal. It involves heating the metal using an induction coil to a high temperature and then rapidly cooling it with a quenching medium. This method is effective for high-carbon and alloy steels.

One advantage of induction hardening is its ability to achieve a greater hardening depth compared to other methods. It is also faster than case hardening. However, it can be more costly than flame hardening and may cause distortion or warping due to uneven heating and cooling.

Laser Hardening

Laser hardening is a surface modification process used to increase the hardness and wear resistance of materials. It involves the use of a high-energy laser beam to heat the surface of a material to a specific temperature, followed by rapid cooling. This rapid heating and cooling process alters the microstructure of the material, resulting in increased hardness.

During laser hardening, the laser beam is directed onto the surface of the material, causing localized heating. The intensity and duration of the laser beam are carefully controlled to achieve the desired hardness. The laser beam rapidly heats the surface, causing the material to reach its austenitizing temperature, which is the temperature at which it becomes fully austenitic.

Once the material reaches the austenitizing temperature, it is rapidly cooled using various methods such as water or air quenching. This rapid cooling, known as quenching, transforms the austenite into a hardened microstructure, typically martensite. Martensite is a hard and brittle phase that contributes to the increased hardness and wear resistance of the material.

Laser hardening offers several advantages over traditional hardening methods. It provides precise control over the hardened area, allowing for selective hardening of specific regions. It also minimizes distortion and reduces the risk of cracking compared to other heat treatment methods. Additionally, laser hardening is a relatively fast process, making it suitable for high-volume production.

This process is commonly used in industries such as automotive, aerospace, and tool manufacturing, where increased hardness and wear resistance are crucial for component performance and longevity. Laser hardening can be applied to a wide range of materials, including steels, cast irons, and some non-ferrous alloys.

Applications of Surface Hardening Process

Surface hardening is a heat treatment process used to improve the hardness, wear resistance, and durability of the surface layer of a material while maintaining the desired properties of the core. It is commonly employed in various industries for a wide range of applications. Here are some common applications of surface hardening processes:

- Automotive Industry: Surface hardening is extensively used in the automotive industry to enhance the wear resistance and durability of critical components such as engine parts, gears, shafts, and camshafts. This helps to improve the overall performance and longevity of the vehicles.

- Aerospace Industry: Surface hardening is crucial in the aerospace industry to increase the resistance of components to wear, fatigue, and corrosion. It is commonly applied to turbine blades, landing gear, and other critical parts to ensure their reliability and safety.

- Tool and Die Industry: Surface hardening is widely employed in the tool and die industry to improve the hardness and wear resistance of cutting tools, molds, and dies. This helps to extend their lifespan and maintain their precision during machining operations.

- Oil and Gas Industry: Surface hardening is used in the oil and gas industry to enhance the wear resistance and corrosion resistance of components exposed to harsh environments. This includes drill bits, valves, pumps, and other equipment used in drilling, extraction, and refining processes.

- Manufacturing Industry: Surface hardening is applied to various components in the manufacturing industry to improve their resistance to wear, fatigue, and deformation. This includes gears, bearings, rollers, and other machine parts that undergo repetitive stress and friction.

- Medical Industry: Surface hardening is utilized in the medical industry to improve the wear resistance and biocompatibility of implants, surgical instruments, and dental tools. This ensures their longevity and reduces the risk of complications during medical procedures.

- Mining and Construction Industry: Surface hardening is employed in the mining and construction industry to increase the durability and wear resistance of components used in heavy machinery, such as excavator teeth, bulldozer blades, and rock drilling tools.