Oil quenching is heat treatment process which involves rapid cooling of heated metals using oil as a quenching medium. This article aims to shed light on the concept of oil quenching, how it works, oil selection, its significance, and the methods employed to achieve optimal results.

Understanding Oil Quenching

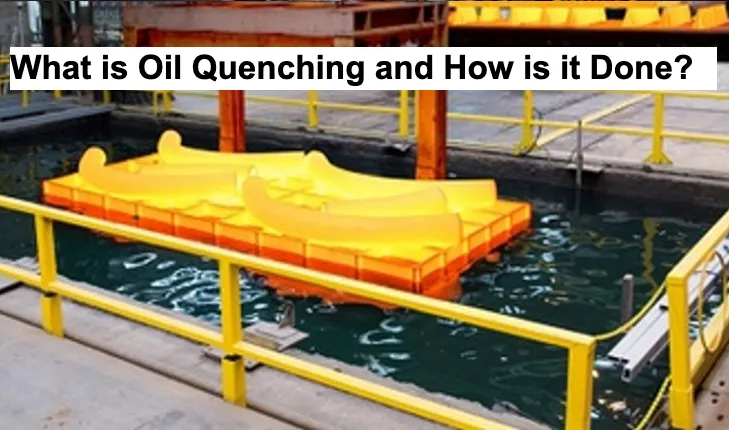

Oil quenching is a heat treatment technique used to harden metals, primarily steel, by rapidly cooling them from elevated temperatures. The process involves immersing the heated metal into a bath of oil, which extracts heat from the material, resulting in a hardened structure. The choice of oil as a quenching medium depends on factors such as the desired hardness, material composition, and the specific application requirements.

How Oil Quenching works?

When a metal is heated to a high temperature and then rapidly cooled, it undergoes a phase transformation. During the heating process, the metal’s crystal structure changes, and upon cooling, it solidifies into a new crystal structure. This transformation affects the metal’s microstructure and, consequently, its mechanical properties.

In the case of oil quenching, the heated metal is immersed in oil, which acts as a cooling medium. The oil absorbs heat from the metal, causing it to cool down rapidly. The rate of cooling is crucial because it determines the resulting microstructure and hardness of the metal.

During rapid cooling, the metal’s crystal structure undergoes a transformation known as martensitic transformation. This transformation results in the formation of a hard and brittle phase called martensite. Martensite has a highly distorted crystal structure, which contributes to its increased hardness.

The hardness achieved through oil quenching depends on various factors, including the composition of the metal, the initial temperature, and the cooling rate. For example, high-carbon steels are commonly oil-quenched to achieve high hardness levels. The rapid cooling rate of oil quenching allows the carbon atoms to be trapped within the martensite structure, increasing the hardness of the steel.

On the other hand, the microstructure of the metal also undergoes changes during oil quenching. Alongside the formation of martensite, other microstructural changes may occur, such as the dissolution of certain phases or the precipitation of new phases. These changes can affect the metal’s strength, toughness, and other mechanical properties.

Stages of Oil Quenching

Oil quenching takes places in three main steps:

- Vapour Stage: In the first stage of oil quenching, a vapour blanket is formed around the submerged part. This occurs because the part is hotter than the quenchant, which is the liquid used to cool the workpiece.

- Boiling Stage: The second stage is the boiling stage, where the quenchant itself starts to boil. During this stage, the submerged parts cool rapidly as the vapour blanket dissipates. This allows the quenchant to come into direct contact with the parts, effectively removing heat through boiling.

- Convective Stage: The final stage of oil quenching is the convective stage. In this stage, heat is removed from the parts through convection and conduction. Convection refers to the movement of the liquid caused by the tendency of hotter and less dense material to rise, while colder and denser material sinks. Conduction, on the other hand, is the transfer of heat through a substance with temperature differences. During oil quenching, the oil is strongly disturbed, causing it to flow upward through the workload, facilitating the removal of heat.

Significance of Oil Quenching

Oil quenching offers several advantages over other quenching methods, making it a popular choice in various industries. Some key benefits include:

- Controlled Hardening: Oil quenching allows for precise control over the hardening process, enabling manufacturers to achieve specific hardness levels tailored to their requirements. This flexibility makes it suitable for a wide range of applications.

- Reduced Risk of Cracking: Compared to water quenching, oil quenching provides a slower and more uniform cooling rate. This controlled cooling minimizes the risk of cracking or distortion, ensuring the integrity of the metal component.

- Improved Ductility: Oil quenching results in a hardened structure while retaining a certain level of ductility. This property is crucial in applications where both strength and toughness are required, such as gears, shafts, and springs.

Methods of Oil Quenching

There are two primary methods employed for oil quenching: immersion quenching and spray quenching.

- Immersion Quenching: In this method, the heated metal is fully immersed in a bath of quenching oil. The oil absorbs heat from the metal, initiating the cooling process. The rate of cooling depends on factors such as the oil type, bath temperature, and agitation. Care must be taken to ensure proper circulation of oil around the component to achieve uniform cooling.

- Spray Quenching: Spray quenching involves directing a high-velocity stream of quenching oil onto the heated metal surface. This method offers faster cooling rates compared to immersion quenching, as the oil is applied directly to the surface. Spray quenching is commonly used for complex-shaped components or when precise control over cooling rates is required.

Factors Influencing Oil Quenching

Several factors influence the effectiveness of oil quenching:

- Oil Type: Different oils have varying cooling rates, viscosity, and thermal properties. Selection of the appropriate oil depends on the desired hardness, material composition, and the specific application requirements.

- Quenching Temperature: The temperature at which the metal is quenched affects the resulting hardness. Higher temperatures generally result in lower hardness levels, while lower temperatures yield higher hardness.

- Agitation: Agitation of the oil bath promotes better heat transfer and uniform cooling. Stirring or circulating the oil ensures consistent quenching results.

Conclusion

Oil quenching is a vital heat treatment process used to enhance the mechanical properties of metals, particularly steel. By rapidly cooling heated metals, oil quenching achieves desired hardness levels while maintaining a certain level of ductility. The choice of oil, quenching method, and process parameters play a crucial role in achieving optimal results. Understanding the principles and techniques of oil quenching empowers manufacturers to produce high-quality, hardened components for a wide range of applications.